Many converters combine digital print with conventional printing techniques, either offline as disparate print steps, or inline in combination or hybrid presses. ‘Although our workflow and editing software will zoom in and provide solutions for specific requirements of each printing process, the bulk of the solutions are agnostic when it comes to the print process. ‘We look at digital printing as just another printing process,’ said Jan De Roeck, director of solutions management. There is also Automation Engine Quickstart with Color Proofing, which allows HP Indigo users to quickly reproduce brand colours with six and seven process inks. Other WebCenter Quickstart packages are offered for corrugated artwork requests and approvals, and brand management. It said that new users can get up and running in just five days.

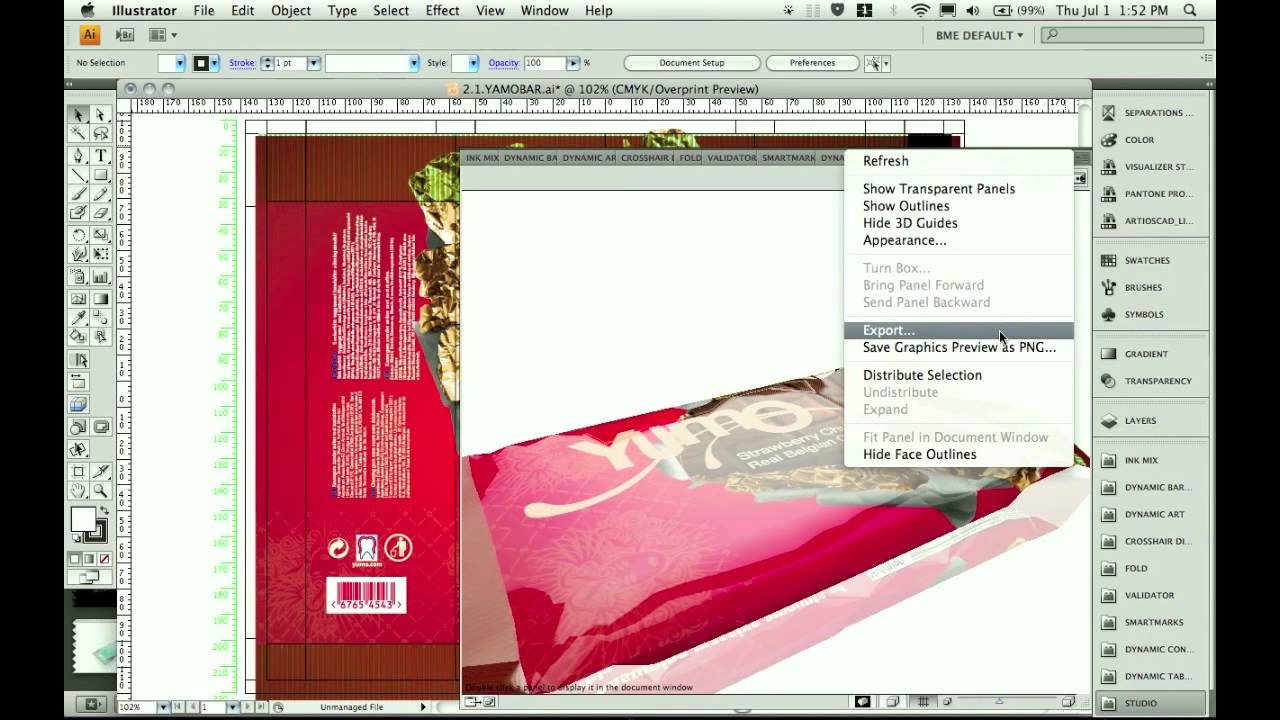

Most recently at Labelexpo Europe 2017, Esko introduced Webcenter QuickStart for Labels, an artwork management system for online customer approvals. The company has standardised on a single production workflow and pre-press server (Automation Engine), however there are still several parallel but compatible design and structural packages with roots in the original separate companies. It claims that nine out of 10 packaging jobs internationally are ‘touched’ by Esko at some point in the production process.

It went on to take over its main competitor Artwork Systems in 2009.Įsko dominates the labels and packaging production software market, from design to output, whether the jobs are destined for digital presses or conventional flexo and litho. A group of mostly Belgian and Danish companies went through a long process of mergers and takeovers, culminating in Esko in 2001, based in Ghent, Belgium. Today’s digital pre-press concepts for packaging and labels started off early in the 1980s. Naturally these come with a host of buzzwords, of which the trendiest are Industry 4.0 (a catch-all term for internet-connected machinery, automation and often robotics), IoT (Internet of Things, ie stuff connected online) and ‘The Cloud’ (current term for remotely hosted programs, often accessed via web browsers). Today’s biggest trends in digital pre-press are automation and remotely hosted programs. Simon Eccles reports on the software systems on the market and how these can optimise your workflows. Automation of the pre-press process remains the biggest trend in digital labels and packaging production.

0 kommentar(er)

0 kommentar(er)